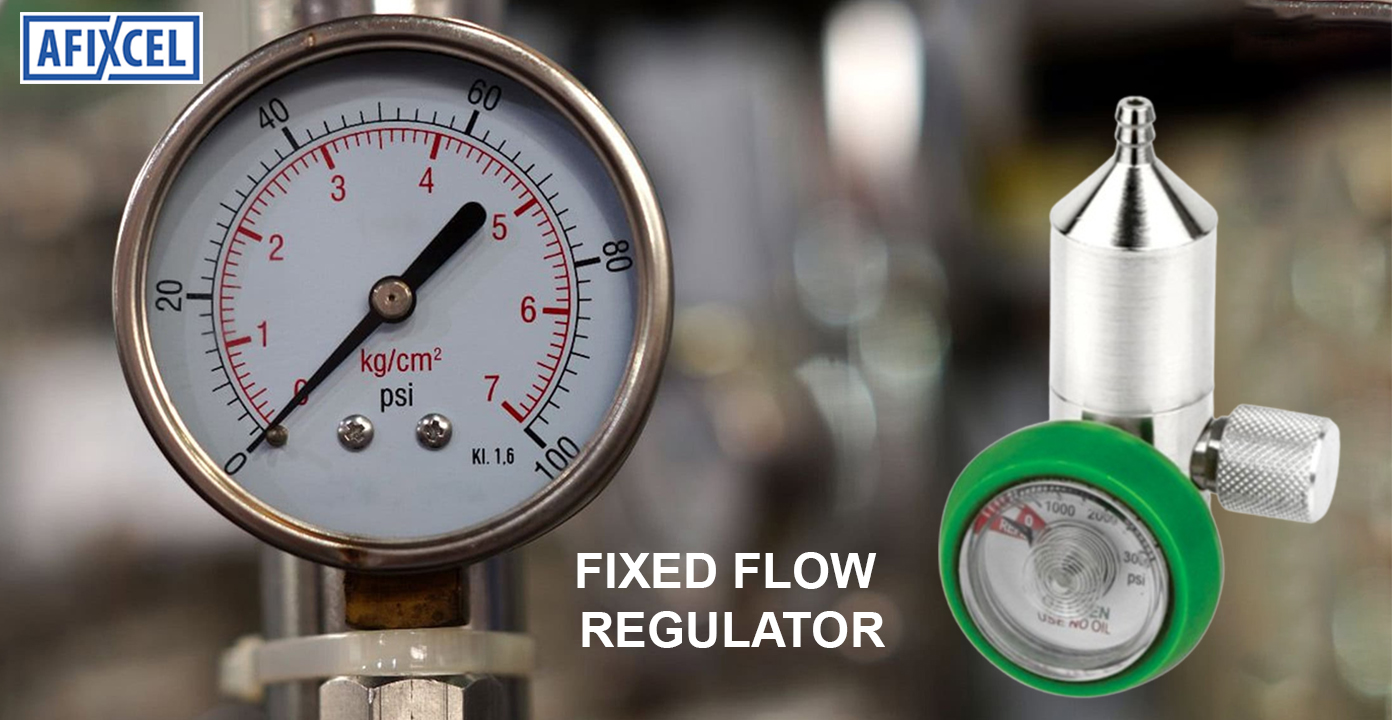

In advanced fluid and gas management systems, the Fixed Flow Regulator stands as a critical control component ensuring accuracy, reliability, and consistency in pressure and flow delivery. Whether in laboratory setups, medical gas systems, or industrial production lines, this device governs how fluids and gases move through pipelines and manifolds to maintain precise flow rates regardless of pressure fluctuations.

Afixcel Engineering, a renowned Manufacturer and Exporter of precision-engineered flow regulators, valves, and fittings, provides an extensive range of control solutions designed to meet the rigorous demands of modern industries.

A Fixed Flow Regulator is a mechanical device engineered to maintain a constant flow rate despite changes in upstream or downstream pressure. The regulator’s core mechanism relies on a precision orifice and a pressure-compensating diaphragm or spring system that automatically adjusts to maintain equilibrium.

In essence, it ensures that systems receive a steady volume of gas or fluid per minute, which is essential for operational safety, efficiency, and repeatability. Afixcel Engineering designs its regulators using advanced metallurgy, CNC machining, and sealing technology to ensure minimal deviation in flow accuracy.

A Fixed Flow Regulator consists of:

The working principle revolves around pressure compensation — as inlet pressure increases, the spring mechanism restricts the orifice opening to maintain a consistent outlet flow. This ensures stable performance across variable operating conditions.

View Products

View Products

View Products

View Products

Due to their precision and adaptability, Fixed Flow Regulators are utilized in a diverse range of applications, including:

Each Afixcel Engineering regulator is tested for compatibility, leak integrity, and precision under simulated operating environments to ensure reliable industrial performance.

Afixcel Engineering’s Fixed Flow Regulators are developed using robust materials and precision-engineered components to ensure consistent operation:

These specifications ensure performance reliability in demanding environments involving corrosive gases, fluctuating pressures, or temperature variations.

Every Fixed Flow Regulator undergoes stringent multi-stage quality assurance processes. These include:

Through these measures, Afixcel Engineering ensures every unit meets or exceeds customer expectations and regulatory standards for global markets.

To meet evolving industrial requirements, Afixcel Engineering incorporates cutting-edge innovations in its Fixed Flow Regulators:

These engineering refinements make Afixcel regulators suitable for both high-purity laboratory applications and heavy-duty industrial systems.

Key benefits of integrating Afixcel Engineering’s Fixed Flow Regulators include:

These attributes collectively improve operational reliability and reduce long-term maintenance costs.

As an industry-recognized Manufacturer and Exporter, Afixcel Engineering focuses on:

The company’s commitment to engineering excellence has positioned it as a preferred partner for flow and pressure regulation components globally.

The next generation of Fixed Flow Regulators is expected to integrate smart monitoring and IoT-enabled diagnostics. Afixcel Engineering continues to research sensor-based feedback systems and adaptive flow algorithms to enhance control precision and efficiency in automation-driven industries.

Q1. What is a Fixed Flow Regulator used for?

It maintains a constant flow rate in gas or fluid systems despite pressure variations.

Q2. Which industries commonly use Fixed Flow Regulators?

They are widely used in medical gas systems, laboratories, pneumatic equipment, and industrial automation.

Q3. What materials are used to manufacture Fixed Flow Regulators?

Afixcel Engineering uses stainless steel, brass, or aluminum for enhanced corrosion resistance and strength.

Q4. Can Fixed Flow Regulators be customized for specific flow rates?

Yes, regulators can be precision-calibrated to deliver desired flow rates for specific gases or fluids.

Q5. How does Afixcel Engineering ensure quality?

Each regulator undergoes helium leak tests, flow calibration, and material verification for uncompromised reliability.

Copyright © 2025 Afixcel Engineering All Rights Reserved.