Pipe fittings are critical components in high-pressure piping systems, ensuring smooth fluid flow, system integrity, and operational safety. The choice of fittings directly influences system efficiency, durability, and leak prevention.

Selecting the correct type of pipe fitting is not just a technical requirement—it is a safety-critical decision. Using the wrong fitting can lead to leaks, system downtime, and even catastrophic failures, especially in industrial environments like oil & gas, chemical plants, and high-pressure water pipelines.

Afixcel Engineering specializes in industrial piping solutions and offers expert guidance to ensure that clients select the right fittings for their pressure, temperature, and material requirements. With years of experience, Afixcel ensures safe, reliable, and efficient piping systems across diverse industries.

Definition & Design:

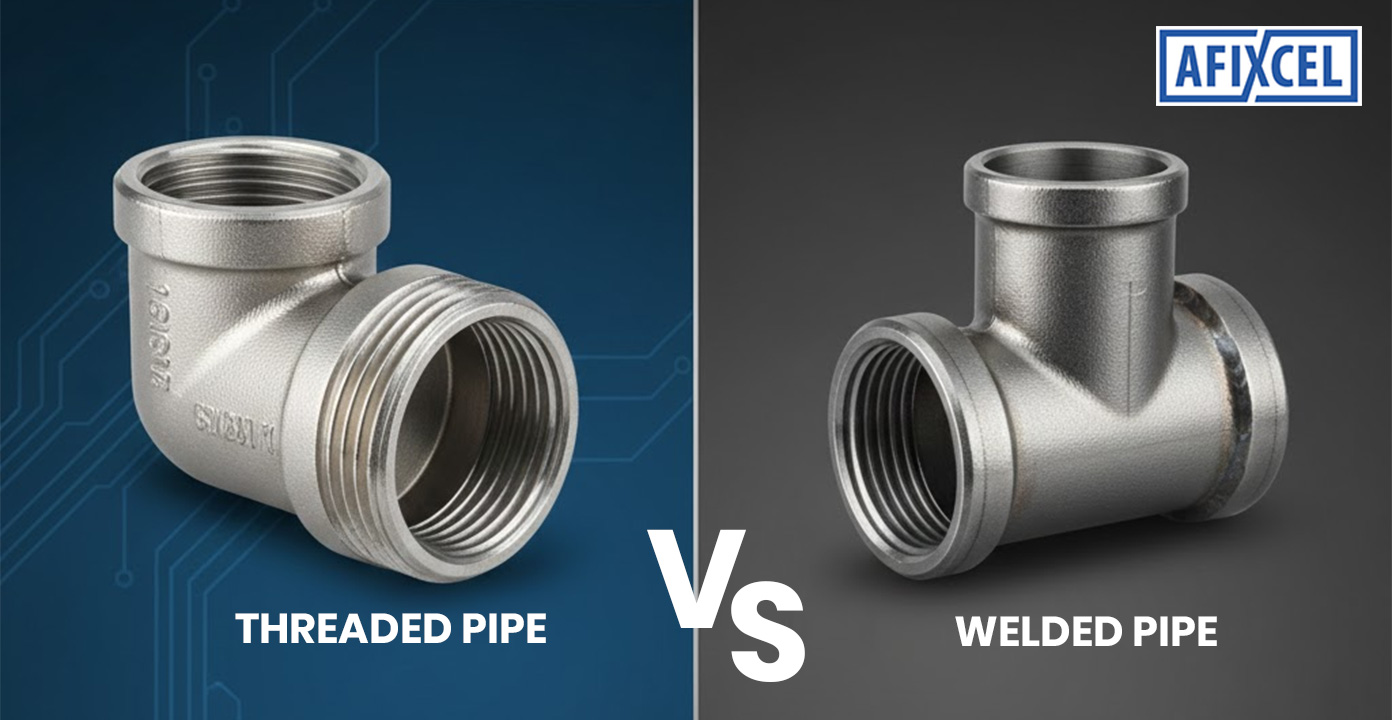

Threaded pipe fittings are components specifically engineered to join pipes using a screw-thread mechanism. The threads, either male or female, interlock tightly with matching pipe threads, forming a leak-resistant connection without the need for welding. These fittings are designed for precision, ensuring that the system remains secure under moderate pressure conditions.

Common forms include elbows, tees, couplings, unions, and adapters, each serving to change direction, split flow, or connect different pipe sizes. Their design allows easy assembly and disassembly, which makes them ideal for maintenance-intensive systems or temporary installations.

Common Materials:

Threaded fittings are manufactured from a variety of materials depending on the fluid, temperature, and pressure requirements. Carbon steel is widely used in industrial applications due to its strength and durability. Stainless steel offers excellent corrosion resistance, making it suitable for chemical and food-grade systems. Brass is often used in plumbing and water systems for its corrosion resistance and ease of machining.

View Products

View Products

View Products

Definition & Welding Process:

Welded pipe fittings are designed for permanent connections in pipelines, providing a continuous joint that withstands high pressures and temperatures. The joining is achieved through welding techniques such as butt welding, socket welding, or seam welding, depending on the pipe diameter and material. Welded fittings are essential in applications where joint integrity and leak prevention are critical. Unlike threaded fittings, they create a seamless connection that minimizes the risk of leakage and can sustain mechanical and thermal stresses over long periods.

Common Materials:

Welded fittings are generally made from carbon steel, stainless steel, alloy steel, or high-strength metal alloys. Carbon steel offers robust strength for high-pressure applications. Stainless steel provides excellent corrosion resistance for chemical, food, and pharmaceutical pipelines.

Alloy steels are used where high strength and temperature resistance are required. The choice of material ensures the fitting can handle extreme operating conditions while maintaining structural integrity and long-term reliability.

Understanding the differences between threaded and welded fittings is crucial for system design, safety, and cost planning.

| Aspect | Threaded Fittings | Welded Fittings |

|---|---|---|

| Installation Method | Screwed onto the pipe using matching threads. No welding equipment required, making installation faster and simpler. | Permanently welded to the pipe using techniques like butt or socket welding. Requires skilled labor and proper welding tools. |

| Pressure Resistance | Suitable for low to medium-pressure systems. Higher risk of leakage under high pressure if threads are not properly sealed. | Ideal for high-pressure applications. Welded joints provide excellent leak resistance and structural integrity under extreme conditions. |

| Maintenance & Replacement | Easy to disassemble, replace, or modify individual sections without affecting the rest of the pipeline. | Difficult to modify once installed. Replacement requires cutting and re-welding, making maintenance more labor-intensive. |

| Cost & Time Considerations | Lower installation costs and faster assembly due to simple threading process. Minimal downtime for modifications. | Higher initial installation cost due to skilled labor and welding equipment. Installation is time-consuming but ensures permanent reliability. |

| Durability & Lifespan | Moderate durability, threads may loosen over time in vibration-prone systems. Best for smaller-diameter or low-stress pipelines. | Highly durable, welded joints can withstand vibration, thermal expansion, and mechanical stresses. Long-lasting even in extreme conditions. |

| Leak Potential | Risk of leakage increases with system pressure or if thread sealing is not perfect. | Welded joints provide seamless connections that are highly resistant to leaks. |

| System Flexibility | Allows easy reconfiguration, expansion, or disassembly of piping systems. | Permanent connections make system changes difficult and costly. |

| Size & Diameter Suitability | Typically used for small to medium-diameter pipes (usually up to 2–3 inches). | Suitable for small to very large-diameter pipes, including industrial and high-pressure applications. |

| Temperature Resistance | Moderate; thread seals may fail under high temperatures. | Excellent; welded joints maintain integrity under extreme temperature conditions. |

| Corrosion & Chemical Resistance | Depends on material and thread sealing; may require additional coatings for corrosive fluids. | Very good if proper material is selected; welding ensures a continuous surface, reducing crevices for corrosion. |

| Application Suitability | Plumbing, HVAC, low-pressure water or gas systems, temporary installations, maintenance-heavy pipelines. | Oil & gas, chemical plants, power plants, high-pressure water or steam systems, permanent industrial pipelines. |

| Safety Considerations | Adequate for moderate systems; improper threading can lead to leaks or accidents. | Superior for critical systems; permanent welded joints reduce risk of catastrophic failure. |

Threaded pipe fittings are widely used in industrial, commercial, and residential piping systems due to their unique combination of simplicity, flexibility, and cost-effectiveness. They are ideal for systems where moderate pressure and easy maintenance are priorities.

Key Advantages:

Welded pipe fittings are preferred in high-pressure and critical industrial applications where durability, safety, and leak-proof performance are essential. By forming permanent joints, they ensure the integrity of the piping system even under extreme conditions.

Key Advantages:

View Products

View Products

View Products

When designing high-pressure pipelines, strength, safety, and reliability are the key criteria.

Comparison of Strength, Safety, and Reliability:

For high-pressure systems, welded fittings generally outperform threaded fittings. Welded joints provide superior strength and resistance to leaks, while threaded fittings may fail under extreme pressure.

Industry Recommendations and Standards:

Engineering standards, including ASME, ASTM, and ISO guidelines, often recommend welded joints for pipelines carrying high-pressure fluids or gases. Safety codes emphasize welding for critical lines to prevent accidents and ensure operational reliability.

Situations Where Threaded Fittings Are Acceptable:

Threaded fittings can still be used in high-pressure lines if the pressure is within moderate limits, the system is non-critical, or temporary setups are required. They are suitable for small-diameter pipelines and systems where ease of maintenance is prioritized.

Proper installation and maintenance are critical for the long-term performance and safety of piping systems.

Best Practices for Threaded Fittings:

Best Practices for Welded Fittings:

Regular Inspection & Safety Checks:

Common Mistakes to Avoid:

Afixcel Engineering is a trusted supplier of industrial pipe fittings, known for high-quality materials and precise manufacturing. They provide solutions tailored to different industries and offer expert technical guidance. All products comply with major industrial standards, ensuring safety, reliability, and consistent performance.

Copyright © 2025 Afixcel Engineering All Rights Reserved.